Overview

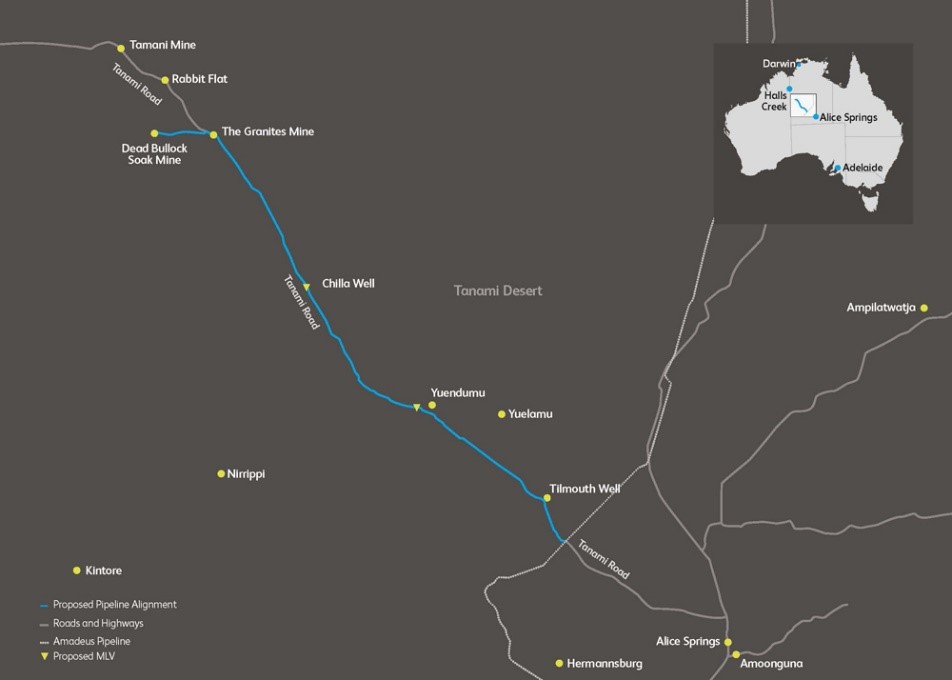

In February 2019, AGIG commenced commercial operations of the 440km Tanami Gas Pipeline. The 8-inch pipeline transports up to 13TJ per day of natural gas to the gas fired power stations at Granites and Dead Bullock Soak, which power the Tanami gold mine in the remote Tanami desert.

Survey of pipeline

Following the alignment of Tanami Road, the pipeline passes through pastoral, Aboriginal freehold and Crown land. Part of the project Front End Engineering Design (FEED) studies included walking the pipeline route to de-risk the construction process. The survey was completed in consultation with the Central Land Council and pastoral landowners to minimise disruption and impact.

Consultations with the communities helped define the final route, with particular consideration given to the existing infrastructure, utilities, pastoral, mining, environmental, Aboriginal heritage and sacred sites impacts.

Detailed engineering and design

This was conducted by our in-house engineering and pipeline design team from late 2017. The project scope included pipeline design calculations and five associated facilities including the inlet meter station adjacent to the Amadeus Gas Pipeline, the two scraper stations and two custody transfer meter stations at Granites and Dead Bullock Soak power stations.

Heritage, environmental and land management approvals

Our in-house land management team negotiated primary agreements with the Central Land Council (CLC) representing three separate native title groups, with three Indigenous Land Use Agreements (ILUAs) and five Section 19 deeds of the Aboriginal Land Rights (Northern Territory) Act 1976 (Cth). In conjunction with the CLC, representing five separate Aboriginal Land Trusts and owners of Aboriginal freehold land. Extensive cultural heritage surveys were undertaken across the pipeline route to ensure sensitive areas were protected and avoided during construction and operation.

Our in-house lawyers and land access professionals negotiated land access and compensation agreements, covering pastoral properties traversed by the pipeline. AGIG worked with stakeholders to minimise disruption, while providing income generating opportunities as a value add component of the construction process.

Both State and Federal environmental approvals were managed in-house, utilising industry expert resources and professionals to provide a sustainable environmental statement in relation to the impacts of the project. All environmental approvals were achieved within 10 months, allowing the construction to proceed in a timely manner.

Technical approvals

The pipeline licence application process was managed by the Department of Primary Industry and Resources using in-house expertise. Subsequent approval stages involved consent to construct, operate and commission. Other key aspects of the approvals included the development of a Pipeline Management Plan and an Asset Management Plan acceptable to the regulators.

Procurement

Our in-house contracts and procurement team lead the undertaking of the contracts processes in an efficient, cost effective, confidential and ethical manner to deliver the best outcomes.

Following quotations from multiple suppliers, we undertook a technical and commercial bid evaluation process, then negotiated final terms and conditions before awarding the contract to the selected suppliers.

The major long-lead contracts for the pipeline included:

• Line-pipe Supply

• Pipeline Construction

• Valves and Major Equipment Package

Construction and commissioning

The construction team began by installing pipeline markers along the easement and moving fencing where necessary. This preceded the clear and grade team who operated bulldozers, excavators and graders to create the right-of-way (ROW). The vegetation and topsoil was removed (to be reinstated at the end of the project) and the stringing crew then trucked the line pipe from the docks in Darwin to the ROW. Excavators lifted the line pipe onto the ROW with specialist vacuum lifts. Certain sections also required a bending crew to match the pipeline to the undulating terrain.

The welding and non-destructive testing crew followed. This is the most labour intensive work group with enough resourcing to move at speeds of around 6 km/day. The coating crew then cleans and wraps the welds with non-corrosive materials to ensure pipeline integrity is maintained. The trenching crew quickly followed and dug to the specified depth of cover. To improve project safety and environmental protection, trenches are left open for as little time as possible, hence the lowering-in crew closely follows the trenching crew. Multiple side booms are used to carefully lift the pipe into the ditch, with padding and backfill crews following closely behind to cover the trench as soon as possible.

The last critical test prior to commissioning is hydrostatic testing. This process involves filling sections of the pipeline with water and compressing to 125% of the maximum operating pressure. Following the hydrostatic testing, the ROW is reinstated in readiness for operations.

The construction was delivered in an isolated location in the middle of Australia in challenging desert conditions. AGIG, together with the pipeline constructors, managed extreme temperatures to deliver the project without any safety incidents, on schedule and within budget.

Operation

Post construction, the commissioning team mobilised – with mechanical and electrical checks of safety valves, metering systems and checking the Supervisory Control And Data Acquisition (SCADA) remote communications are correctly transmitting data to the AGIG control room. Once signed off and regulatory approval granted, the pipeline was dried before introducing natural gas. The system pressure is incrementally increased with system checks at each megapascal (MPa) of pressure. Once the pipeline passed all commissioning checks, the system was handed over to operations in the electronic asset management system. This ensured the Asset Management Plan and associated processes developed by the in-house technical and operations teams were ready for operations. The operations team will then undertake preventative and corrective maintenance for the entire life of the pipeline.

Practical completion

Practical completion after commissioning the Tanami Gas Pipeline was achieved by February 2019, and Newmont's power stations are currently taking gas.